Remember when a voltage meter would be a perfect indicator of your remaining battery capacity?

That was with lead-acid batteries.

Now we have lithium batteries, and monitoring the charge of the batteries isn’t that easy anymore.

Why is that?

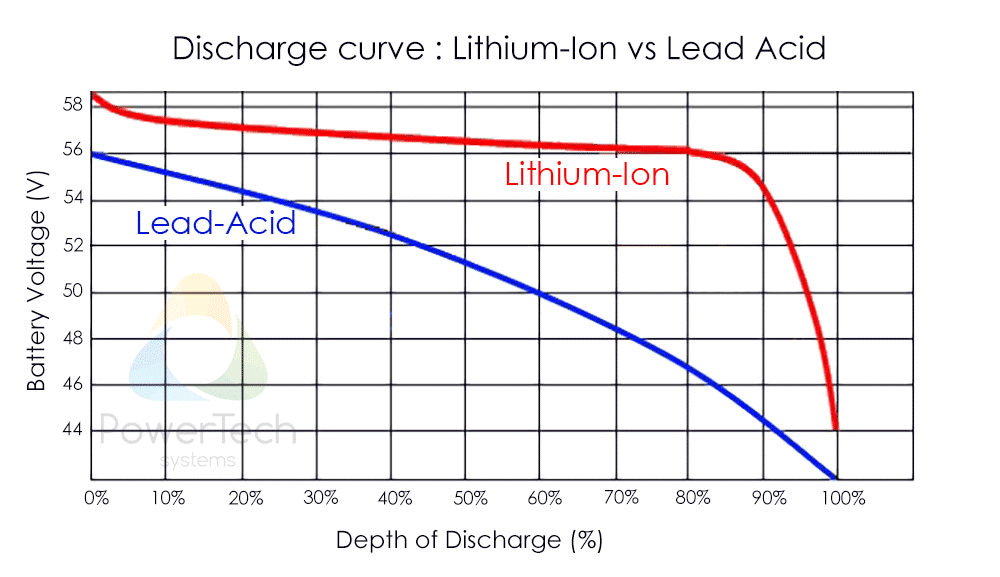

The voltage curve of a lead-acid battery is predictable. As you can see in the following image:

We can see that 50% equals 51V for the lead acid battery. However the Lithium battery curve is very flat, making it hard to determine the state of charge. Here, 50% could be between 56V and 57V, which is 20-80%, which is a huge difference.

See where I’m getting at?

That’s why we need a different device to measure the state of charge on a lithium battery.

Introducing the Battery Shunt

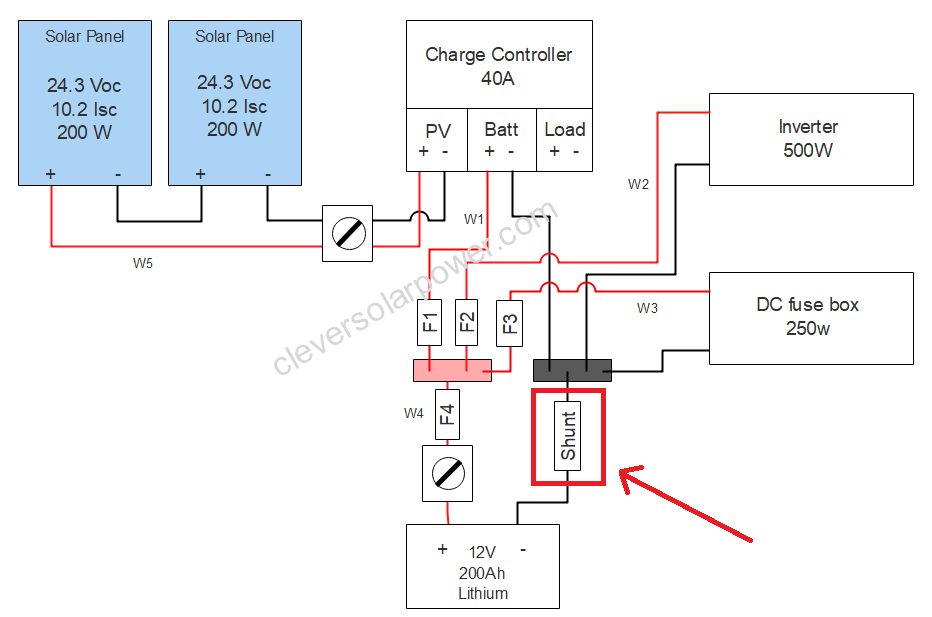

A shunt is a device you install on the main battery negative in your system. It measures all the energy going through it, both charge and discharge. Let me show you a diagram:

How Does a Shunt Work?

A shunt is a resistor known for its precision, allowing for accurate current measurement. It’s used in conjunction with a voltmeter to calculate the amount of current flowing through a circuit. This is based on Ohm’s law, which states that the current through a conductor between two points is directly proportional to the voltage across the two points.

In the context of measuring battery capacity, an electrical shunt works in the following manner:

- Shunt Placement: As we have already seen, a shunt is placed in series with the battery’s negative.

- Voltage Drop: When the battery is used, current flows through the shunt, creating a small voltage drop. The shunt is designed to produce a voltage drop of 50-100mV at its rated current, so it’s very predictable and consistent.

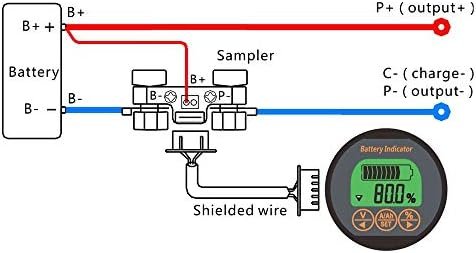

- Voltage Measurement: This voltage drop is then measured using a voltmeter. The meter is connected in parallel to the shunt (across its terminals) to measure the voltage drop accurately. We will see this extra wire later in the article.

- Current Calculation: Given the known resistance of the shunt, and the measured voltage drop across it, Ohm’s law (I = V/R) is used to calculate the current flow.

- Battery Capacity: If you measure the current over time (say, an hour), you can calculate the battery’s capacity. Battery capacity is usually in ampere-hours (Ah) or Watt-hours (Wh). So, if you measure a steady current of 1 amp for one hour, you’ve consumed 1 Ah of capacity. If the current varies over the hour, you will integrate (or sum up) the current to find the total capacity used. The shunt itself does these calculations.

In battery monitoring systems, these measurements are often done digitally, with the results processed by a microcontroller and then displayed to the user, typically showing the current flow, the consumed capacity, and sometimes an estimate of the remaining capacity based on the current consumption rate. This calls for a display to view a battery’s charge state.

Click here to read my guide on recommended battery monitoring systems.

How to Wire a Shunt

Wiring a shunt is relatively easy and is similar to other brands.

Connect the main battery negative to the shunt to B-, then use another cable from P- to your main negative busbar. After the main negative busbar are your loads and charging equipment. So, all the power going in and out of the battery is going through the shunt.

There will be a smaller wire that needs to be connected to the battery positive. This must be as close to or on the main positive battery terminal. This is for a reference signal from the battery. It then can calculate the difference in voltage drop, like we discussed earlier.

Different types of shunts

There are two different types of shunts:

- One-way shunt (power meters)

- Two-way shunt (battery meters)

You need the ones that measure in and out (two ways). Otherwise, you won’t have a complete overview of your SOC.

To get a complete overview of the best shunts, click here.

One way Shunt

Why should you use a one-way shunt? People like to read how much current or watts they get from solar or is going to their inverter. That is what it does. It measures the power going through a wire. Here are some examples:

Two ways Shunt

Two-way shunts are more popular in off-grid solar systems. They offer a complete visualization of your battery’s state of charge.

Shunt Displays

We will need a display to show the battery’s state of charge. These displays are mostly the same. There will be a plug on the shunt itself where you have to plug the wire into, and then you will have it working. The shunt and the display work together, so you cannot get a shunt from brand A and a display from brand B.

You need to enter the battery’s capacity and charge it until it’s full. Then you set the capacity to 100%.

There are also options from Victron where you only have the app with Bluetooth. This is quite cumbersome because you must take out your phone to see the state of charge.

Here are some popular options:

What size shunt do you need?

As you might already have seen, there are different sizes in shunts. Some of the most common ones are:

- 100A

- 350A

- 500A

The size of the shunt depends on the load or charge power (choose the biggest).

Let’s say you have a 1000W inverter on a 12V system. Then you will draw:

1000W/12V=83A

We then multiply with a 1.25 safety factor:

83A x 1.25 = 104A -> we can use a 100A shunt

If your system is bigger, then you need a larger shunt. Most people should go with a 350A or 500A shunt. The price between these variations will not be that high.

Conclusion

A shunt is a device that measures the energy going through it and displays it on a monitor.

Installing one is straightforward. Programming can be done in a few seconds.

If you have a lithium battery, I highly recommend getting a shunt.

I’m an off-grid enthusiast. I created this website to give clear and straight-to-the-point advice about solar power. I’m also the author of the book ‘Off-grid solar power simplified‘. Read more about me on my about page, check out my Youtube channel, or send me a message.

Hello,

I have a question. I wish to monitor my boat batteries. I have 2 x SLA crank batteries wired parallel. The 2 SLA are 100Ah each (200Ah total). When I crank the motor the 70A alternator chargers the 2 SLA. When the motor is off I have 200Ah of usable power. Max is 50% in fact because of SLA or no less than 12.2V. I always leave the battery switch on “both” position. I currently monitor the voltage. I wish to install a 500A shunt with monitor. Where do I actually place the shunt to monitor;

* the 2 SLA when motor is not running and

** the 2 SLA when motor is running

Regards,

Franco

Check the diagram in the post, wiring it in is easy.