- Lead-acid battery: 12V 400Ah

- Lithium Battery: 24V 100Ah

Let me explain how these values are calculated:

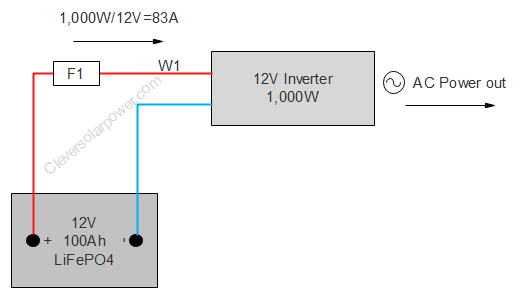

Determining the Number of Batteries For a 1,000W Inverter

Step 1. Determine Current draw

The current draw depends on the battery voltage. Most readers of my website will have a 12V battery, so we will use 12V as an example.

1,000W/12V= 83A

The inverter will draw a current of 83A from the battery.

If we repeat the same calculations for a 24V and 48V battery system:

1,000W/24V= 41A

1,000W/48V= 20A

We can see that the current will decrease if we increase the battery voltage.

We will use the current draw in step 3.

Step 2. Determine C-rate

Next, we need to consider the battery C-rate. These are the C-rates for the most used battery chemistries:

- Lead-acid: 0.2C

- Lithium-ion or LiFePO4: 1C

The C-rate is how much current we can draw from a battery. We have to multiply the C rate by the capacity of the battery.

- Lead acid: 100Ah battery * 0.2C = 20A

- Lithium: 100Ah battery * 1C = 100A

Step 3. Determine the Amount of Batteries

To maximize the lifespan of our batteries, we need to consider the C-rate of the battery.

Remember from step 1 that a 1,000W inverter on a 12V battery will draw 83A?

Lead-acid

According to the C-rate (step 2) of a single 12V 100Ah lead-acid battery, we can only draw 20A.

To maximize the lead-acid battery life, we need four 12V 100Ah batteries. This is how:

12V 100Ah battery * 4 in parallel = 12V 400Ah battery

400Ah * 0.2C = 80A of current draw

The current draw of 83 Amps matches the current draw of the C-rate.

We will have to connect four 12V 100Ah lead-acid batteries in parallel.

Lithium

We can have a higher current with lithium because lithium batteries have low internal resistance.

To maximize the lithium battery life, we need one 12V 100Ah battery. This is how:

100Ah * 1C = 100A of current draw

We can see that lithium is preferred. Check out my expert review article: Best lithium battery

Fuses and Wire used

F1: 83A * 1.25 = 103A -> 100A fuse

W1: 4AWG or 25mm²

How long will a 1,000W inverter run?

The runtime of a 1,000W inverter depends on:

- The battery capacity

- The load you’re running

This can get technical, so if you don’t want to read all these steps you can fast-forward to the example.

To calculate the runtime, you need to follow these steps:

- Determine the load (in watts) you want to run on the inverter. For example, if you have a 400-watt appliance, the load will be 400W.

- Determine the battery capacity (in amp-hours or Ah) and voltage (V) connected to the inverter. The battery capacity and voltage will determine how much energy can be provided to the inverter.

- Calculate the available energy in watt-hours (Wh) from the battery. Multiply the battery capacity (Ah) by the battery voltage (V).

- Factor in the depth of discharge (DoD) and efficiency. Most batteries shouldn’t be fully discharged to maximize their lifespan. For example, if you’re using a lithium-ion battery with a recommended DoD of 80%, multiply the available Wh by 0.8. For lead-acid, this is 0.5. Also, consider the inverter efficiency (typically around 85-90%). Multiply the adjusted Wh by the efficiency factor (0.85 or 0.9).

- Divide the battery available energy (Wh) by the energy consumption of the load (W) to find the runtime in hours.

Let’s calculate this with an example. The Most-used example my readers ask for is a fridge.

A fridge typically draws an average of 50 watts. This includes the off-times.

We have a 12V lithium battery with a capacity of 100Ah, as shown in the diagram before. We need to calculate the total amount of usable energy in the battery:

12V * 100Ah = 1,200Wh

Now we can only use 80% of that capacity for the battery to have a long lifespan. We also need to factor in the efficiency of the inverter at 90%:

1,200Wh * 0.8 usable capacity * 0.9 inverter efficiency = 864Wh of usable stored energy

Now we need to divide the available energy with the used energy:

864Wh/50W = 17 hours or run time.

If you increase the battery capacity you can run the fridge for longer.

Conclusion

You need one 12V 100Ah battery or four 12V 100Ah lead-acid batteries in parallel to run a 1,000W inverter.

We have also calculated the runtime of the inverter with a fridge which was 17 hours.

If you have questions, feel free to leave a comment or send me an email.

Read more:

[custom-related-posts title=”Related Posts” none_text=”None found” order_by=”title” order=”ASC”]

I’m an off-grid enthusiast. I created this website to give clear and straight-to-the-point advice about solar power. I’m also the author of the book ‘Off-grid solar power simplified‘. Read more about me on my about page, check out my Youtube channel, or send me a message.

is the first battery described like a lythiom one otherwise i dont understand the answer. sorry. Im old.

No, what you are saying is lithium-ion (Li-ion). Those are the batteries in your phone and laptop. The ones I’m talking about are lithium iron phosphate (LiFePO4).

Thank you very much for this information, it has been of great help.

Thanks a lot for the information, so how many 300 W solar panels are needed for powering 400Ah batteries and 1000W inverter also what size of charge controller is needed

Assuming your battery is 12V, You have a total of: 400Ah*12.8V=5120Wh. You have to recharge it in one day, assuming you have 3 sunhours per day. 5120Wh/3h=1700W of solar panels. 1700W/300W=6 panels.

you then have to figure out how much panels per mppt charge controller. Total= 1700W/14.4=120A. You better upgrade to 24V battery with that many solar panels.