I’ve seen terrible advice when I googled how many batteries you need for a 3000W inverter.

I would say 90% of the guides on this are wrong. So, take the time to read this one thoroughly. It will be worth it. I promise you.

- Lead-acid batteries have a C-rate of 0.2C, while lithium (LiFePO4) batteries have a higher C-rate of 1C.

- To manage current and cable size, adjust battery voltage

- 12V for inverters below 1000W.

- 24V for 1000-2000W inverters.

- 48V for 2000-4000W inverters.

- For lead-acid: 48V 300Ah Battery

- For lithium: 48V 100Ah Battery

We need to satisfy two criteria before we can tell you what battery you need. These are:

- C-rate (in this case, discharge)

- Current

C-rate

The C-rate of a battery is the rate at which the battery can deliver the promised capacity of a battery. For example, the C-rate of a 100Ah lead-acid battery is 0.2C. That means that we can discharge the battery with a 20 Amp load (100Ah x 0.2= 20A). You can discharge the battery with a higher load, say 40Amps, but then the battery capacity will be reduced because of internal heat generation.

The C-rate of lithium batteries (LiFePO4) is 1. That means a 100Ah battery can be discharged with a 100 Amp load.

We want to respect the C-rate of the battery because that will give us the longest battery life. If we abuse the battery by discharging it at a higher current than it’s made for, the battery will get damaged, and its lifespan will decrease.

- Lead Acid C-rate: 0.2C

- Lithium (LiFePO4) C-rate: 1C

Current

The second point is the current drawn from the battery to the inverter. We do not want to draw lots of current from the battery to the inverter. If we do, we need big and heavy cables. Big and heavy copper cable means a lot of money.

Another point here is that if you crimp the wires yourself, you want to limit the current. Your crimping tools might not be suited for a high current application. Therefore, we need to be safe and reduce the current. I recommend not going over 100 Amps if you create the system yourself.

Now, how do we reduce the current in the wires?

Easy!

Increase the voltage.

These are my recommendations for system voltages to their inverters:

- 12V battery system -> inverter below 1000W

- 24V battery system -> inverter from 1000-2000W

- 48V battery system -> inverter from 2000W to 4000W

- More inverter power -> Have multiple inverters in parallel

If you want to run a 3,000W inverter, you should have a 48Volt system. This will reduce the current to a safe level in a DIY system. If we calculate the current, it will be 3000W/48V=62.5A.

Now imagine having a 3,000W inverter on 12V: 3000W/12V= 250A!

Read my article about my recommended inverters for off-grid solar here and why a 48V battery is better than 12V.

Putting It All Together

We know that we need to have a battery that has enough capacity to satisfy the c-rate and we need to have a 48V battery.

Lead-acid

If we build this system with 12V 100Ah lead-acid batteries, we can calculate the following:

We know that we need a 48V system. That’s 4 batteries in series.

If we put 4 batteries in series we have one 48V 100Ah battery.

The c-rate of lead-acid is 0.2C. We can draw 100Ah x 0.2C = 20Amps. That’s not enough to power the 3,000W inverter.

We saw previously that we need 62,5A if we have a 48V system. That means we need three parallel strings of 4 batteries in series for a total 12 batteries.

That is how you efficiently run a 3,000 inverter on lead-acid batteries.

Lithium

If we do the same calculations for a 12V 100Ah lithium battery, we become the following:

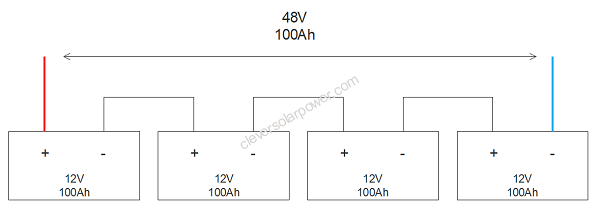

We still need a 48V system. So the 4 batteries in series stay the same.

We now have a 48V 100Ah lithium battery.

The c-rate of lithium is 1. We can draw 100Ah x 1C = 100Amps. That is enough to power a 3,000 watt inverter without over-working the battery.

You need to have 4 lithium batteries in series to power a 3,000 watt inverter.

How many 100Ah batteries do I need for a 3000 watt inverter?

You need 4 Lithium batteries in series to run a 3,000W inverter. If you use lead-acid batteries, you need 12 batteries with 4 in series and 3 strings in parallel.

Can I run a 3000 watt inverter on one battery?

You can but it’s not recommended because you will reduce the battery lifespan, or the BMS will stop the discharge. The battery size I recommend for a 3000W inverter is a 48V 100Ah server rack battery. Make sure the discharge rate is higher than 0.5C.

Conclusion

Figuring out what kind of battery you need to run a 3000-watt inverter is not as straightforward as you think. Hopefully, you know now how to put your system together. Remember that lithium is cheaper in the long term.

Watch my video about the topic here:

Read more:

I’m an off-grid enthusiast. I created this website to give clear and straight-to-the-point advice about solar power. I’m also the author of the book ‘Off-grid solar power simplified‘. Read more about me on my about page, check out my Youtube channel, or send me a message.

Very impressive. I am supporting you 100 percent,b y buying your book.

Thank you!

Hi Nick,

I agree with SEJANAMANE, this is great info and I love the way you present and organize the details. I also picked up the book!

Thank you!

What a marvelous explanation

Thanks Nick.

Thank you!

Good day SEJANAMANE

I am about to go off grid.

I have a 200/250w solar panel

a 30a control charger

A db box with 4-6 breakers at 32a fuses one is 10a for the lights… And a 200ah lead solar battery.

I had a 1500w inverter it burnt out.

But i now want to get a 3000watt inverter

How do i go about my system now what will i need?

Another battery?

Another control charger

Bigger fuses

Bigger solar panel

Please help!

Kind regards.

Kaylin Lance Dawson.

The maximum current you should draw is 40A (200Ah*0.2C-rate). A 12V, 3000W inverter will draw 250A max. You need to increase your battery capacity to 400Ah and get a 1000W inverter instead. That will give you a max current draw of 83A. That is a properly sized system.

Super. Thank you so much.. I did forget to mention that the load i want to put on the inverter is over 1500watts daily use(appliances) {no heated appliances}.

How many batteries should i have for a 3000watt inverter and should my charge controller (30a) be bigger as well as the fuses in the db box (32a)

For the current: 3000W/48V=62A or 3000W/24V=125A. Up to you to choose 24 or 48V. I recommend using server rack lithium batteries.

Lithium: 125Ah*0.5C=50A => 48V,125Ah (6kw) or 24V,250Ah

Ok so i figured that

1000w-2000w inverter will be safe on 2x 12v batteries of 200ah correct?

So if my load is say 1400w (all appliances)

Is it safe to say i can run a 1500w inverter on 1x 12v 200ah battery as not all the appliances that = 1400w will be operating at the same time and those that will be will = to 780w(appliances) used throughout the day, on and off (on from 8am-12pm and off from 12pm-4pm and on again from 4pm-10pm.

Hi Nick,

Thank you for your effort to clarify and educate. I am going to buy the book for sure. Now if the 3000w inverter is written “12V” can I still increase my battery bank to 48V?

Thanks for getting the book. No, you will need to use an inverter suited for 48V.

Best explanation ever

the whole c-rate thing was what i was missing

Thanks!

awesome thanks for the info.

quick question I have eight 12v 20Ah how many to power my home? I have 12 100 watt panels could you please give me some info on what I should do please and thank you, I too am getting your book..

Hello Roy, first, you need to find out how many kWh you need in a day. The worst-case scenario would be winter. From there you can fill in my off-grid load calculator. This is located in the top menu. From there you can go and put your system together.

if I want to start with about 1000W need but plan to grow, which is best, to purchase the larger inverter & 12V battery up front and grow battery capacity as needed or purchase a smaller inverter and battery and upgrade batteries and inverter as needed.

If you know your loads will increase, you should get the bigger inverter. However, you need to size the wires and fuses based on the bigger inverter. That’s going to cost you more. Alternatively, you can add more inverters in parallel to increase the output later. Then you need a more expensive inverter that can do this. Keep in mind the idle current of a bigger inverter is bigger.

Thank you for sharing your knowledge. Much appreciated Nick

Hi, looking to confirm my RV solar system is safe:

SOLAR PANELS:

-Solar-2 x 400 w Piemar panels/parallel to 150/50 Viltron MPPT controller (Open circuit voltage 50.39V, Current @ PMAX 9.69A

-Solar-1 x 400w Piemar panel to 100/30 Victron MPPT controller

BATTERY BANK:

-Battery bank is 3 x 200AH SOK lithium batteries in parallel (see cabling for connection details)

INVERTER:

-Inverter is Victron Multiplus II – 12/3000w / 120-50A 2x120V

– Output of Victron inverter connected to onboard breaker distribution panel which powers all RV appliances and outlets etc. as per factory build (6/3 cable). I have disconnected the factory RV converter from the panel.

12 VOLT DISTRIBUTION SUB PANEL:

-Connected to Victron power distribution bar with 6 gauge cabling (powers 12 volt items i.e. slides/aux. lights etc.)

RV HOUSE GENERATOR:

-Onboard ONAN 5500w gas generator connected through transfer switch with 50A shore power then onto input of Victron inverter

CABLING:

– Cabling consists of 1/0 from Victron power distribution bar to DC on inverter (3 feet), 1/0 from battery bank to Victron distribution bar (each battery cabled to distribution bar separately with separate 600A isolation switches – rationale was if any one battery or BMS failed I could isolate and have independent redundancy). Cabling from MPPT controllers to Victron distribution bar is 6 gauge, cable from rooftop solar panels to MPPT controllers is 10 gauge.

FUSING:

-parallel solar panel array input cable wired to 12 volt-30A breaker box then to Victron power distribution bar (60a mega fuse on bar)

-single panel input cable wired to 12 volt-30A breaker box then to Victron power distribution bar (60a mega fuse on bar)

-12 volt distribution panel protected 60a fuse on power distribution bar

-each + battery cable protected – 200A fuse on power distribution bar

-inverter+ DC input protected – 450A mega fuse between the inverter and power distribution bar.

-each solar array cable from the breaker box protected with 60a mega fuse on the power distribution bar

– + cable from power distribution bar to levelling jacks protected with 100a mega fuse as per manufacturer

I was concerned about installing a 12 volt system vs. 24 or 48 but in the end opted for 12 volt with what I thought was appropriate gauge welding cable. I would appreciate your comments.

Hello Cam,

I cannot go into every detail of your system. Please refer to my fuse and cable sizing guide on the website.

I do not recommend sticking with 12V because you will draw 250Amps. For a 3000W inverter I recommend a 48V system, 24V is doable but don’t recommend it.

I recommend reading my book so you will not waste your money on the wrong components.

appreciate your response, why is 12 volt not acceptable with appropriate cabling? my 3 x 200 AH lithium batteries are connected individually to a Victron Distribution bar (rated at 1,000 A) with appropriate fusing. I am not questioning your advice just looking for additional explanation. All my cables are professionally crimped so I am not concerned with 250A shorts (etc.). thank you

Hello Cameron,

Good question. I have these guidelines that are shared with many other experts. The main reason is that a DIY crimp is not as good as a professional crimp. Additionally, the cost of the wire will be very high if you have a 12V battery and a 3000W inverter. I’m not saying you cannot do it, but I do not recommend it. Another reason is voltage drop if your cables are long. You have professionally crimped cables and you already have your components, so you don’t need to change that.

My load need is arround 500w. Is it still ok to get 48v 3000w inverter as i am planning to increase my load in the future?

Yes, if you upgrade your load, ensure you have the right batteries to support it.

hey Nick, this was really helpful.

one thing I want to clarify, if I need a 3000watt inverter for my needs, instead of 4x 12v 100Ah lithium batteries, can I use 2x12v 200Ah?

The 12v vs 48v has me confused, as all batteries available are 12v, does the 48v system refer to once all batteries are connected? or does it mean it has to have 4 X 12v batteries in the series not inclusive of amp hours?

I hope my question makes sense.

The other question I have is for solar panels – we have 4 X 270 watt panels – is this sufficient to recharge the system?

Thanks so much for your help and time .

Good questions.

1. The highest voltage with 2x12v 200Ah will be 24V (two in series). The current will be: 3000W/24V=125A. The C-rate of lithium is 0.5 or 1C, depending on the BMS inside. Since the battery is 200Ah, a battery with 1C will be ok (200Ah*1C=200A). A battery rated at 0.5C will not be sufficient(200Ah*0.5C=100A).

2. The 48V refers to the total battery voltage. These can be 8x6V batteries, 4x12V batteries or even 16×3.2V cells.

3. 4x270W=1080W*3hours a day = 3240Wh. you need to recharge the battery in one day. Your battery capacity is 4800Wh. You need at least 6 of these panels to recharge the battery. I recommend using my calculator here

Hi. I am a little confused on the powering of an inverter. I have a Magnum 4000 watt inverter with e-panel. It is a 24 volt system. I have 4 L16 x 6 volt Rolls Surrettes batteries (450 amp hr). Cables to inverter are 2 gauge and are factory crimped (about 4 feet long). I have 500 watts of solar and 500 watts of micro hydro (approx). I have been running a 16 cu. ft refrigerator, 7. 5 cu. ft. freezer, 2 tv’s, led lights, computer for almost 10 years on these flooded batteries with no major issues. I recognize my batteries are at end of life and am looking to replace them with lithium. it would seem to me using your recommendations that I do not have enough battery power at 24 volts to run my inverter properly. Am I correct?

If I read correctly, your battery is 24V @450Ah. You should only be drawing: 450Ah*0.2C=90A, but with a 4000W inverter you draw 166A.

While you can draw more than double the C-rate, I do not advise it because you will degrade your batteries faster.

Because you said you would change to lithium, you need a 24V battery with at least 332Ah to have a 0.5C.

If I have a 3000w inverter and a 100ah battery and the load is small will it damage the battery? or will the battery still drain very fast?

If you have a lead-acid battery, you should only have a 240W load. (0.2C*100Ah*12V=240W) To have the recommended C-rate. You can always go higher than that, but your battery lifespan will reduce, and there will be additional losses because of heat generation. Plus your 3000W inverter probably uses +-50W standby power without any loads attached. If you have LiFePO4 then replace 0.2C by 0.5C or 1C (depending on the manufacturer specs).

Hi Nick,

Very interesting, we have just purchased a 3000w inverter for our van, we don’t plan at this stage running eg aircon. Only smaller appliances occasionally. We also have 2 x 120amph lithium batteries. will this be ok?

Hello Donna, as long as your load is lower, then it’s ok to have a 3kW inverter. But you need to size your wiring according to a 3kW inverter. Check my article about wire sizes and fuse sizes. 3000W/12V=250A -> your battery is 12V 240Ah*0.5C=120A, if your battery can handle 1C, which it should then it becomes: 240Ah*1C=240A, so it is close to your limit. If you pull 3000W from the inverter, your battery will disconnect.

Hi Nick,

I have 4 100Ah lithium batteries for my 3000w inverter. Can I increase the lithium batteries to 8 or 12?

Thank you

Yes, but you need to keep the voltage the same of the inverter. If your 4 batteries are wired in parallel to become 12V, then you need to wire 8 or 12 batteries in parallel too. The more batteries you wire in parallel, the more uneven they will be charged and discharged. I recommend using a busbar if you have more than 4 batteries in parallel.

Hi nick,

I am running two separate Sungold inverter’s a 12Kand a 6K. Both 48volts.

Presently the 12K has four aolithium 48volts 512K 100ah rack mount batteries

And the 6K has one wall battery UFO lithium 10K 200ah

Can I make these batteries one bank and power both, or should I add one more 512 to the 6K as the UFO tends to drop out now and again, but when I add an extra lithium to the UFO it does not drop.

All batts are 48volt

All inverters are 48 volts.

Each inverter is fed by 24, 300 watt panels..

Thanks for reading.

Phillip

Great info, by the way..

Hello Phillip, yes you can have the batteries in parallel if they are the same voltage. Read my article about it here.

I guess, I should have been more precise..

Can I power both inverters from the combined battery bank if the batts are all parallel?

Will it cause a problem in having two inverters charging the same battery bank?

Both inverters can charge and discharge the batteries. Hope this answers your question.

Thanks nick..

I purchased your book and it’s my new go to..

I forwarded this site to all my friends..

Thanks for your service.

I have a small Green house I was planning on going completely solar with what would I need to run 3 600 watt HPS lights for Max 18 hours a day your information is so helpful thus far just want to make sure I’m going the safest and best route with batteries and inverters

Thanks!

Hello Evan, I recommend using my calculator here. And sign up for my email list here where you get a lot of tips and tricks + free diagrams to get you started.

Hey Nick

I have a 3000 inverter rated as below.

inverter mode:

Rated power 3000/2400w

DC input: 24vdc,100A

Solar Charger mode:

Rated 1000W

System Voltage 24VDC

VOC: 100vdc

Can I run it on 48v system?

No, the specifications say its 24V. It would be more useful if you share the brand and model number here.

hi

can any one help me to solve my problem .as below mentioned

in my house the total loads exactly 2990 watts . I want to known how many solar panel i need and size of battery and inverter . the sunlight 6 hors per day . the usage of power may be full loads in night and 50% in a day. and please attach the calculation steps thanks a lot

Hello Hazza,

It’s impossible to figure that out without knowing the appliances and how long they will run.

You should put your values into my calculator here. You will then find out how many batteries and solar panels you will need.

hi Nick

please see my load calculation and correct my if it is wrong

25 lamps x 40w 220v ac -25×40=700w

1 refrigerator 170w 220v ac =170w

1- washing machine 180w 220v ac 180w

3- outlet socket for mobiles charge let us said 100w

so the total loads =700+170+180+100=1150

the sunlight 6 hors in average between summer and winter

so 1150*6=6900

the availability of solar panel in my area 200w

so if we multiply peak power rating *operator factor

200*0.75=150w actual output *companied efficiency

150*0.85=127.5

127.5*6 hors per day=765

finally we dividing total load 1150w/765=1.69

mean i need two numbers of solar panel and 1500w inverter and 150amp lithium battery

please correct me if some things is wrong .and if don’t mind

explain the right one ..best regards

and

Nick – just reading your articles on qty of batteries for 2K and 3K inverters. Sure appreciate your thorough explanations. Other articles seem to focus on increasing capacity of batteries by wiring in parallel. Is your method to reduce amperage resulting in lower Ah decreasing your capacity for time off grid? Does your method compromise time (Ah capacity) to reduce wire size and component size and save money? Am I missing something that you still have plenty of capacity or are charging some way to maintain capacity? Thank you.

Hello Dave, Have you watched my video about a 3,000W inverter on 12Volts? if not, view it here: https://youtu.be/-Zcn74IWlGQ

And another video about choosing 12 or 24V for campers here: https://youtu.be/-OP0aEPgzqs

So, if I series 4 each 12v 100AH LifPO4 batteries to make a 48V system do I have to worry about the 100A BMS in each of those batteries conflicting? I’m not 100% on how the BMS work and interact with one another.

If that is an acceptable setup it seems it would be much cheaper than buying a 48V 100AH rack battery. Also, what are the advantages of a rack battery over a 4 x 12v battery setup be, if any? I’d like to have as much battery storage as possible but at $1300 – $1500 a pop on rack batteries I could build 2 sets of 48v with 12v 100 AH batteries.

Just ordered your book on Amazon today. Glad I found this website!

Good question Gregory! I recently made a video about this, check it out here: https://youtu.be/-OP0aEPgzqs (the part at the end).

It’s better to have a server rack because then you can balance all the cells. If you have 4 batteries in series, then battery one doesn’t know the state of charge of battery 2 and so on. The charge controller just charges the whole pack to 56.8V, it doesn’t see the batteries as separate. So it can be that battery 1 is higher voltage and battery 2 is lower voltage. Hope this makes sense. Wit ha server rack every cell is monitored by the BMS.

i have not seen a detailed explanation like what you have done in this article.

thank you very much, i have learnt so much

Thanks Jonathan!