Solar Photovoltaic (PV) systems are complex electrical installations requiring wires with different gauges (thickness), materials for the conductor, core type, and insulation. Wires used for PV installations have to be listed in the National Electric Code, but the particular wire configuration for each part of the installation depends on several factors, including a choice taken by the installer or the homeowner.

Picking the right wire among the suitable options according to US regulations ensures you have a safe electrical installation that provides appliances with the right voltage and current. This article will explain everything you need to know about the different wires used in each section of a PV installation.

Wire Categorization: Material, Core, and Insulation

Wires are usually categorized by their materials, core design, and insulation. In this section, we will explain how wires are categorized varying on these configurations.

Materials: Copper, Aluminum, or CCA?

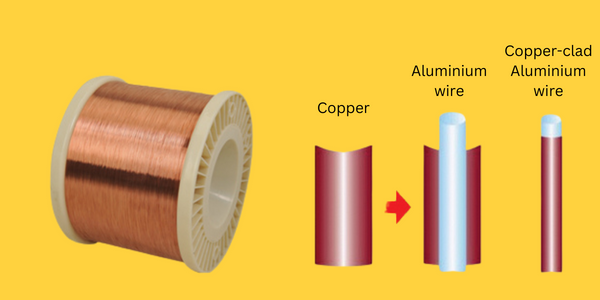

Pure copper wires have a conductivity of 5.98×10⁷ (S/m) at 20°C and resistivity of 1.68×10-8 (Ω•m) at 20°C. These wires also feature better mechanical properties than pure aluminum and Copper Clad Aluminum, making them stronger and ideal for most applications.

Aluminum wires weigh around 30% the weight of copper wires and are also much cheaper, but they have a low conductivity of 3.5×10⁷ (S/m) at 20°C and higher resistance of 2.82×10-8 (Ω•m) at 20°C.

Copper Clad Aluminum (CCA) hits the sweet spot between copper and aluminum. These cables have 1.5x the resistivity of pure aluminum and feature a higher conductivity, their weight is around 40% that of pure copper wires, but they also feature a reduced cost. The main disadvantage of CCA wires is that they are more vulnerable to rupture than copper wires, making them a slight power transmission hazard.

If you use wires other than copper, look at the ampacity of the aluminum cables instead of copper cables.Core: Stranded or Solid Core?

Solid core wires feature a single thread of thick material, while stranded wires consist of several thinner wires twisted in a bundle.

Stranded wires are more flexible and malleable, making them ideal for most applications, especially fitting inside electronics or traveling through oddly shaped pipes in electrical installations.

Solid core wires are more robust and resistant but harder to manage. These properties make them better for outdoor usage where durability and resistance to harsh environments are necessary. Solid wires can also handle higher currents and are sold cheaper.

Insulation: PVC, Rubber, and Cross-Linked Polyethylene

AC and DC electrical wires are insulated using polyvinyl chloride (PVC), Rubber, and Cross-Linked Polyethylene (XLPE). The insulator might feature different materials and properties depending on the acronym letters for a particular cable. The most used acronyms are the following:

- T: Thermoplastic (Temperature Rate of at least 60ºC).

- X: Cross-Linked Polyethylene (XLPE).

- R: Rubber insulation.

- H: Heat Resistance (Temperature Rate of at least 75ºC).

- HH: High-Heat Resistant.

- W: Water Resistant.

- N: Nylon Jacket.

- -2: Flame Resistance (Temperature Rate of 90ºC)

Aside from cables featuring regular acronyms, Underground Usage Entrance-2 (USE-2) wires used for underground installations are important to mention.

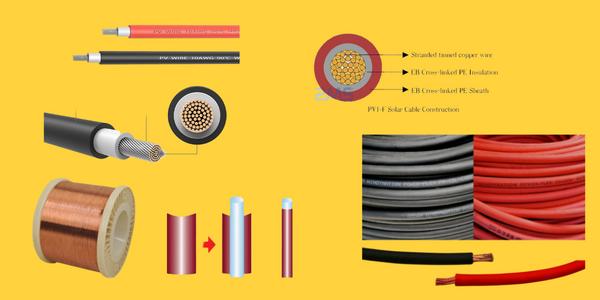

Another important mention is the PV Wire, which can resist extremely hot environments of up to 150ºC, are water, and UV-resistant, and can withstand harsh environmental conditions, making them ideal for rooftop and grounded PV installations.

The following table lists the most commonly used wires and their properties:

| TW | THW | THWN | THHN/ THWN-2 | RHW-2 | USE-2 | XHHW-2 | PV Wire | |

| Temperature rate | 60ºC | 75ºC | 75ºC | 90ºC | 90ºC | 90ºC | 90ºC | 90ºC (Wet)

120 – 150ºC (Dry)1 |

| Flame Resistant | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Heat Resistance | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| High-Heat Resistance | ✓ | ✓ | ✓ | ✓ | ||||

| Gas & Oil Resistance | ✓ | ✓ | ||||||

| Light UV Resistance | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Heavy UV Resistance | ✓ | |||||||

| Water & Moisture Resistance | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Table 1: Comparison of Regularly Used Wire Insulations

1Temperature rate varies slightly on the manufacturer.

Wires Used for PV Installations

As you better understand wires and how they are categorized, it is easier to learn about typical and recommended wires used for each section of a PV installation.

If you want to learn more about calculating wire sizing, read my article about it here.

Solar Panel Wiring

Solar panels must be installed using specially designed wires to withstand harsh environmental conditions on rooftops and different installation sites. PV wires are specially designed for this purpose, making them the typical choice for PV installations. These cables even have the unique ability to withstand extremely high voltages of up to 2,000V.

Wires like USE-2 and RHW-2 can withstand relatively harsh environments, making them suitable for wiring underground PV installations, but they cannot withstand more than 600V as PV wires can.

Battery Cables

Energy storage systems are usually installed in safe environments, making the only wire requirement that they can withstand high heat as batteries charge and discharge. Considering this, batteries regularly use THHN/THWN-2, RHW-2, and XHHW-2 wires. It is strongly recommended to use copper wires, providing batteries with wiring that can withstand harsh electrical conditions.

Wires for DC Applications

DC appliances use low voltage and demand a higher current, meaning that wires used for DC appliances might get heated more often than AC ones for appliances demanding the same power. Most cables in the list can be used for DC applications, especially if the appliances demand low currents. For connections in the DC side of a PV system (charge controller, DC loads, inverter inputs), we recommend wires with a temperature rating equal to or superior to 90ºC.

Wires for AC Applications

AC applications can use most wires from TW up to XHHW-2, varying the wire on the particular application. Since AC wires are usually passed around the house inside pipes, they do not tend to require water-resistant insulators, but this can be an important feature to have in case of pool areas or sectors of the house where there might be contact with water.

The conductor for standard residential and commercial AC applications tends to be a copper THW or THWN type of cable. However, electricians can switch selections depending on the desired properties for the electrical installation, the budget, and the expected current demands.

I have written a book that contains all the information you need to get started with off-grid solar power.

I have written a book that contains all the information you need to get started with off-grid solar power.

With over 1,800 reviews at 4.5 stars, I can almost guarantee that this book will save you $100s on buying the right equipment.

You can get it here on Amazon.com

I’m an off-grid enthusiast. I created this website to give clear and straight-to-the-point advice about solar power. I’m also the author of the book ‘Off-grid solar power simplified‘. Read more about me on my about page, check out my Youtube channel, or send me a message.

Nice work

I’m writing Technician handbook and have used your diagrams. Will send you a copy through E-mail.

You may not copy my diagrams because they are protected by copyright. Doing so will be a copyright infringement, and necessary steps will be taken to combat the infringement.

Hey, thanks for all this, very helpful!

How about tinned copper wire? In particular in the case of stranded wires. Does it affect the conductivity?

Tinned copper wires are good. Just make sure they are not aluminum.