A BMS is a device that helps take care of a battery. It makes sure the battery is being used safely and efficiently. It does this by monitoring the battery and ensuring it doesn’t get too hot or cold. It also monitors the voltage to ensure it doesn’t get too full or too empty. It also helps balance the individual battery cells to stay at the same voltage.

A BMS is used in things like electric cars, portable electronics, and other devices that use a lithium battery. It’s important to have a BMS to make sure the battery is working well and to keep it from getting damaged.

How Does a BMS Work?

One of the main parts is a microcontroller, a tiny computer controlling the BMS. The microcontroller is connected to a bunch of wires that measure the temperature and the voltage of the battery.

The BMS also has some other parts that help it do its job. For example, it might have some switches that can turn the flow of electricity to and from the battery on and off. It might also have fuses or other protective devices to help keep the battery safe in case of a short circuit.

When the BMS works, it uses the voltage sensors’ information to ensure the battery is used safely and efficiently. It might turn off the flow of electricity to the battery if it gets too hot or cold or too full or empty. It might also balance the battery to ensure all the different parts work together.

Overall, a BMS helps ensure the battery is working well and helps keep it from getting damaged. It’s an important part of many devices that use batteries, like electric cars, portable electronics, and more.

What is Balancing a Battery?

Balancing a battery refers to ensuring that all the cells in a battery pack are charged to the same level. This is important because cells in a battery pack that are not balanced can suffer from overcharge or over-discharge. This can shorten the battery’s life or reduce its overall capacity.

Several different methods can be used to balance a battery. The most common approach is to use a passive balancing system. This type of system uses resistors to discharge power from fully charged cells while allowing cells not fully charged to continue charging. This helps ensure that all the cells in the pack are charged to the same level.

Another method of battery balancing is active balancing. This uses electronic switches to transfer charge between cells as needed. This is a more efficient way of balancing. Instead of wasting the energy as heat, it gets put into other cells.

Why do you need a BMS in a Battery?

The primary functions of a BMS are to:

- Monitor the individual cells in a battery pack to ensure they operate within a safe and optimal range.

- Protect the battery pack from overcharge, over-discharge, and overcurrent conditions that could damage the cells or cause a fire.

- Balance the cells in the battery pack to ensure that they are all charged to the same level and prevent imbalances that could shorten the pack’s life.

- Provide information about the battery pack’s status, such as its charge level, voltage, and temperature, to the user or other systems needing it.

Can You Have a Battery Without BMS?

Without a BMS, the battery may not be protected from overcharge, over-discharge, or overcurrent conditions. This can damage the cells or, even worse, cause a fire or meltdown. It may be more difficult to monitor the battery’s status, such as its voltage and temperature. This will make it harder to determine when the battery needs to be charged or replaced.

If you decide not to use a BMS, you need to bottom balance your cells. I have made an article about how to do this for LiFePO4 which you can read here. Bottom balancing the cells is often used for electric vehicles.

Can You Have a BMS in Parallel?

I assume we are talking about having multiple batteries in parallel. If so then yes, you can have multiple BMS’es in parallel. Let’s say you have a 48V battery on the shelf and want to add a second one. Every battery has its own BMS. You can then combine the output of both batteries into one output.

Another situation is that you have one battery with two BMS’es. If one fails or burns out, the other can still deliver. I have never tried this personally, but I don’t see why it shouldn’t work. There are also special medical grade batteries with two BMS’es inside, so if one fails, the other takes over. However, this is on the same circuit board.

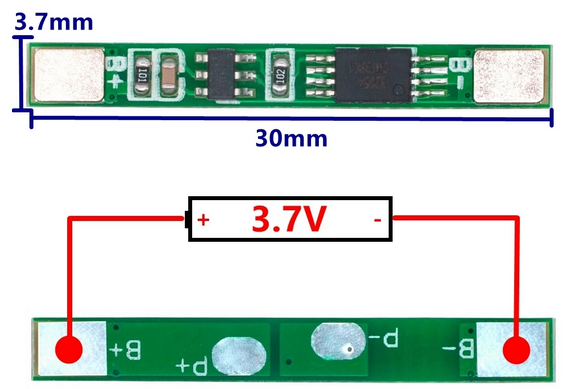

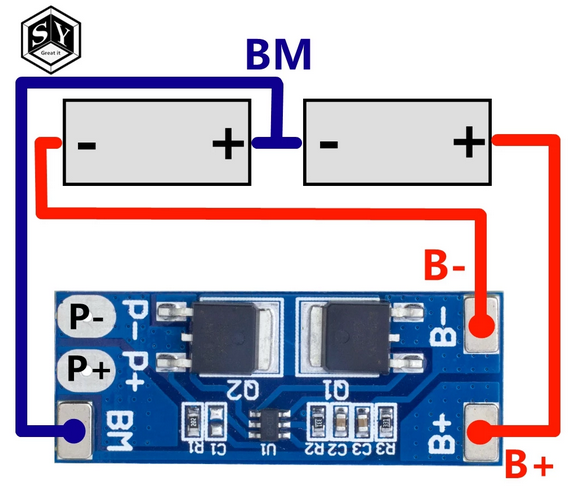

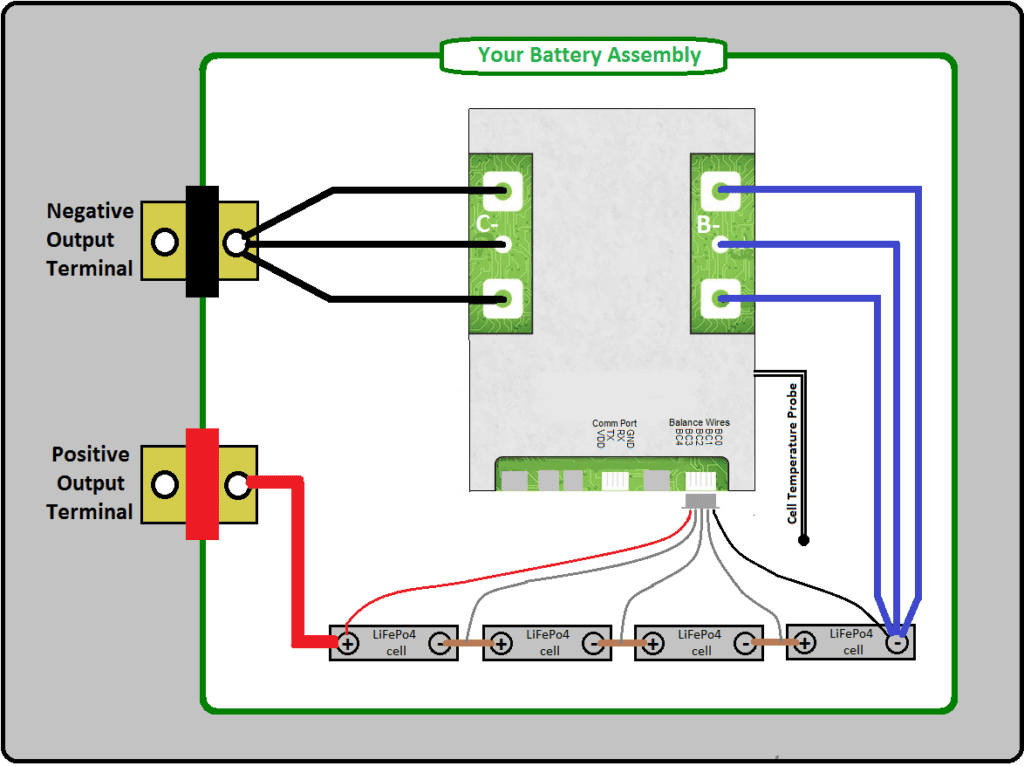

How to Wire a BMS?

Wiring a BMS is straightforward once you know the basics.

The BMS has two negative connections. One is called C- and one is called B-. The C- will be your main battery negative. The other (B-) will go to the main negative post from the battery cells.

Then you need to connect the balancing wires.

- wire 0 will go to the main negative

- wire 1 will go to the first positive

- wire 2 will go to the second positive

- wire 3 will go to the third positive

- wire 4 will go to the fourth positive

These small wires will detect the voltage of every cell and send it back to the BMS for processing. Depending on the results, the BMS will do certain things like stopping the charge, starting the charge, balancing, or reducing the current,…

The last positive cell will be your main positive of the battery.

What BMS do you Need?

There are several different BMS’es available. The first is current, and the second is the number of cells you have. Let’s start with the desired current. It is also important to check which lithium chemistry the BMS is made for. Is it made for LiFePO4 or Li-ion? I have written an article on how to choose the best BMS here.

How to Calculate a BMS?

Let’s assume you have a 12Volt battery. The total power of the inverter is 1000 watts. You then need to use the following calculation to determine the current of the BMS:

1000Watts/12V=83A

I recommend adding a 20% safety factor to this.

83A x 1.2 = 100A

We can now see that we need a 12V 100A BMS. I recommend overkill solar.

Different Types of BMS: 4s, 8s, and 16s

Most 12V batteries have 4 cells in series. That’s where 4S comes from. If you have a 24V or 48V system, you can have 8 cells or 16 cells in series. This is because every cell is 3.2 volts.

If you have for example, a 16 cell battery it will be a 48V battery. You then need a 16S BMS. The maximum power a 100A 16S BMS can deliver is:

100A x 48V = 4800Watts

Including our 20% safety margin:

4800W x (100/120) = 4800W x 0.83 = 4000W

I have written a book that contains all the information you need to get started with off-grid solar power.

I have written a book that contains all the information you need to get started with off-grid solar power.

With over 1,800 reviews at 4.5 stars, I can almost guarantee that this book will save you $100s on buying the right equipment.

You can get it here on Amazon.com

I’m an off-grid enthusiast. I created this website to give clear and straight-to-the-point advice about solar power. I’m also the author of the book ‘Off-grid solar power simplified‘. Read more about me on my about page, check out my Youtube channel, or send me a message.