I often get asked how many watts their MPPT charge controller can handle.

I then ask, how many amps is your charge controller, and what is your battery voltage?

So, if we know these two variables, we can easily calculate the number of watts a charge controller can handle.

- Battery voltage

- Charge controller current

Battery voltage

The higher your battery voltage, the better.

Why, you might ask?

If we increase our battery voltage, then the current reduces.

Let’s explain this with an example:

400W/12V = 34A

400W/24V = 16A

You can see that with a 12V battery, we would need a 40A charge controller and only a 20A charge controller if we use a 24V battery.

Increasing your battery voltage will save you money on the charge controller.

Charge controller current

Finally we have the charge controller current.

The current indicated on the charge controller of let’s say a victron is 100V/20A

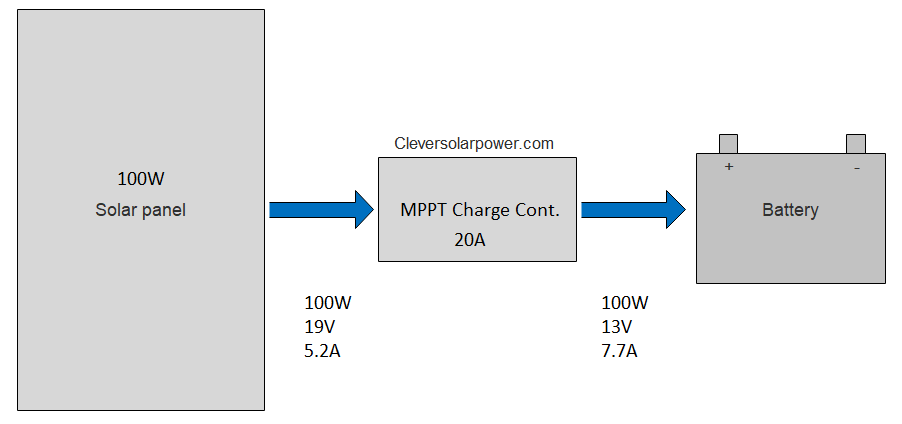

20 Amps is the current amount sent to the battery, not the input current from the solar panels. Both are different values, as you can see in the diagram below:

19V, 5.2A input and 13V 7.7A output to the battery.

Read more: what size MPPT controller do i need?

Calculating the amount of watts a charge controller can handle

Now with the theory out of the way, let’s apply some math.

If we have a 20A charge controller and a 12V battery we can have a maximum amount of:

13V * 20A = 260W

Easy!

Now does that mean you can have several 50W panels hooked up to a charge controller?

No.

Let me explain to you why.

If we take the specifications of a 50W solar panel:

- Wp: 50W

- Isc: 2.48A

- Voc: 23.9V

If we put 5 panels in series, we become 250W. As we have calculated, this is under the 260W, so we are all good right?

Not so quick.

If we put these panels in series, we become:

23.9V * 5 panels in series * 1.25 = 149V DC

We will have 149 input voltage to the charge controller. Now if the charge controller were a 20A 100V charge controller, this would not work. It might even damage the charge controller permanently.

You need to keep your panels under the recommended input voltage of the charge controller.

In this case, I would recommend using a 2S2P configuration which means two panels in series and then paralleled together.

23.9V * 2 panels in series * 1.25 = 60V DC

This would be a better system and not damage the charge controller.

Remember that it’s essential to check the max input voltage of the charge controller before you buy your components.

[custom-related-posts title=”Related Posts” none_text=”None found” order_by=”title” order=”ASC”]

I’m an off-grid enthusiast. I created this website to give clear and straight-to-the-point advice about solar power. I’m also the author of the book ‘Off-grid solar power simplified‘. Read more about me on my about page, check out my Youtube channel, or send me a message.